Industry Applications

For ten years, SATEC has been providing top technology service provider for mixing and granulation in various industries.

TECHNOLOGY/PRODUCTS

German technology, focusing on mixing and granulation technology in the field of raw material preparation technology

Mixing and granulation

Granulation technology

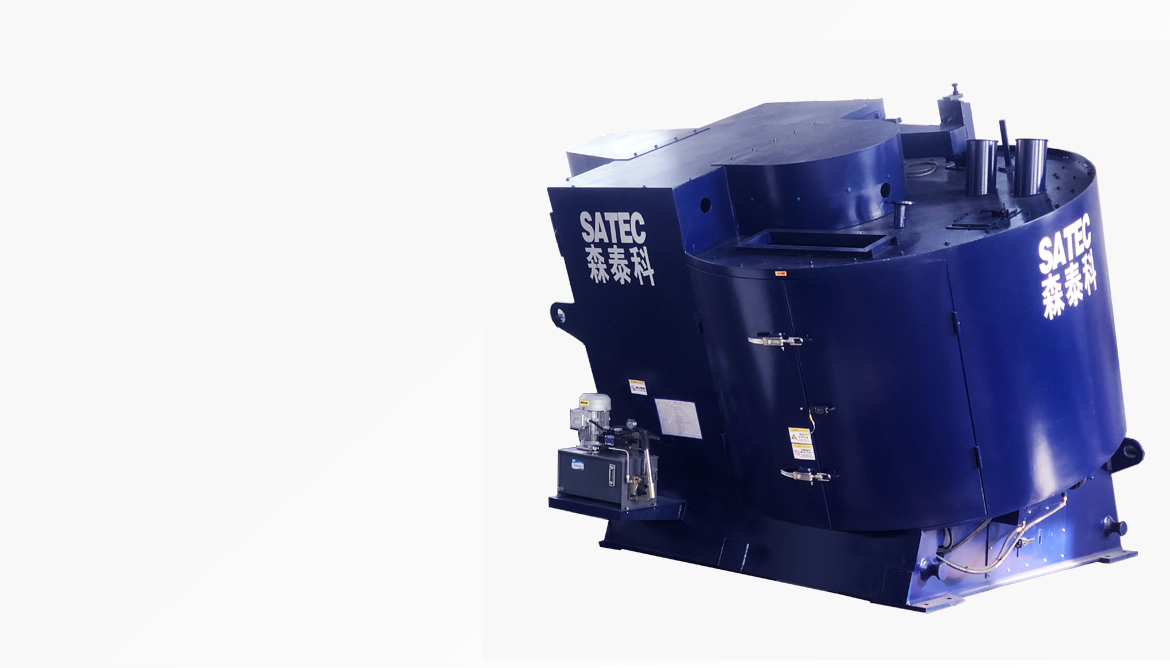

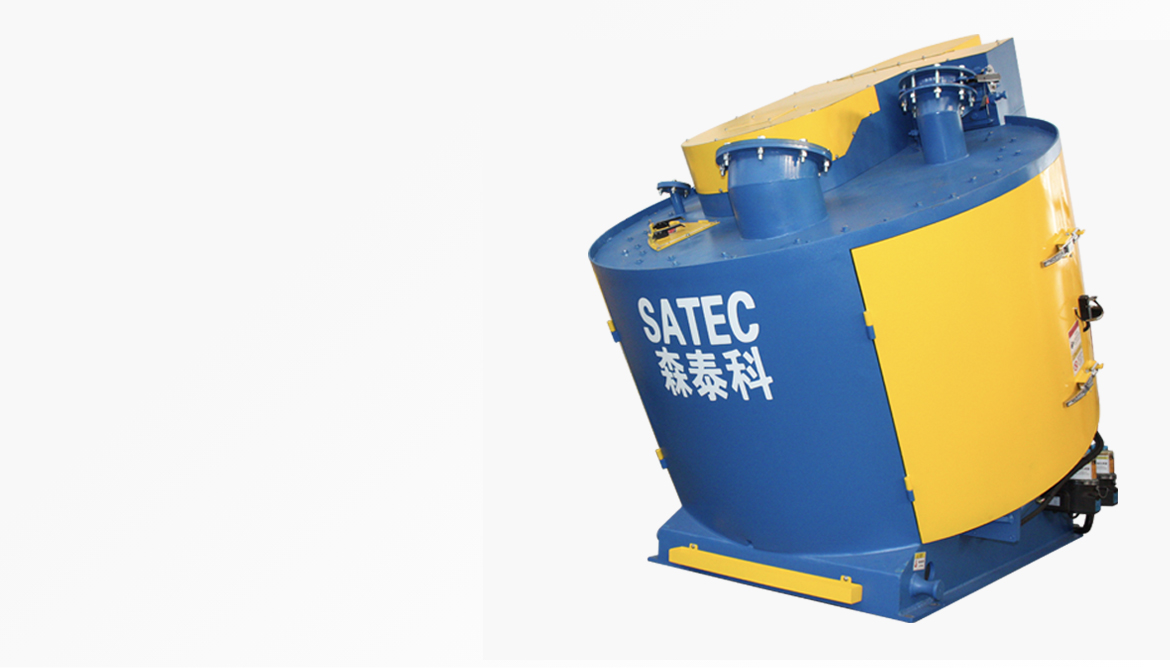

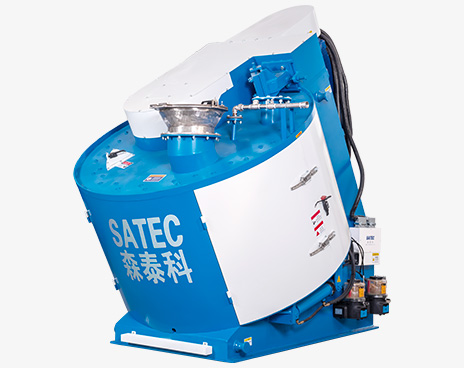

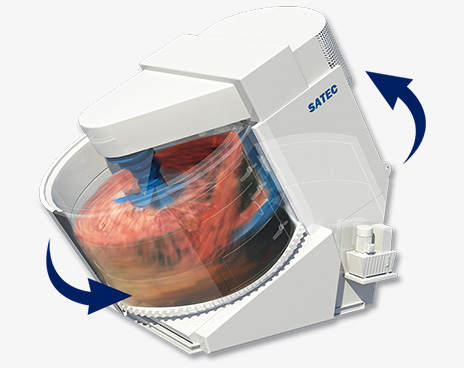

Intensive mixer

Mixing granulator

Why choose SATEC?

Multi-party cooperation and strong strength

Since its establishment, SATEC's intensive mixer has cooperated with many domestic Chinese academies of science, colleges and universities, and participated in more than 20 large-scale single-machine and large-scale ingredient projects in the first half of 2022, and has occupied an important position in important foreign economic regions.

Special materials, rich industry experience

SATEC's intensive mixer has a lot of successful experience in processing special materials and special industries, such as electromagnetic, lithium battery, nano-level chemical raw materials and other industries.

Technological innovation - rotating discharge door

In terms of discharging, the SATEC intensive mixer has realized the function of rotating discharging door, which is a technological innovation for the intensive mixer stand-alone product.

Intelligent module control technology

In terms of equipment control, the PLC-5G system independently developed by SATEC's intensive mixer can realize fully automatic monitoring and intelligent module control technology, which is unique.

Complete and excellent design team.

In terms of team building, SATEC intensive mixer has a complete and excellent design team with high level of skills, fast solutions, and accurate and high-quality solution drawings!

Provide complete one-stop whole-plant production line design

It can not only realize the design, manufacture and production of single machines, but also provide a complete one-stop whole-plant production line design, and provide a full set of auxiliary equipment and design solutions for storage, transportation, weighing, feeding and a complete set of process control systems.

Project Cases

News Center

Experimental accuracy and durability of the mixing granulator

2025-08-07 14:24:17

The laboratory mixing granulator has significant advantages in experimental accuracy and equipment durability, which are mainly reflected in the following dimensions

SATEC's intensive mixer demonstrates strong mixing capabilities

2025-05-06 14:16:07

SATEC's intensive mixer has demonstrated strong mixing capabilities in the field of industrial mixing. Its technical features and advantages make it the preferred equipment in many industries.

What are the factors that affect the mixing uniformity of the intensive mixer?

2025-08-06 14:16:07

In the process of using intensive mixer to mix materials, mixing uniformity is one of the important indicators to measure the mixing effect.

Intensive mixer: a powerful assistant for industrial production

2025-08-06 14:16:07

With its innovative technology and modular design, SATEC's intensive mixer has become a benchmark equipment in the field of industrial mixing.

Partners

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory