Intensive Mixer

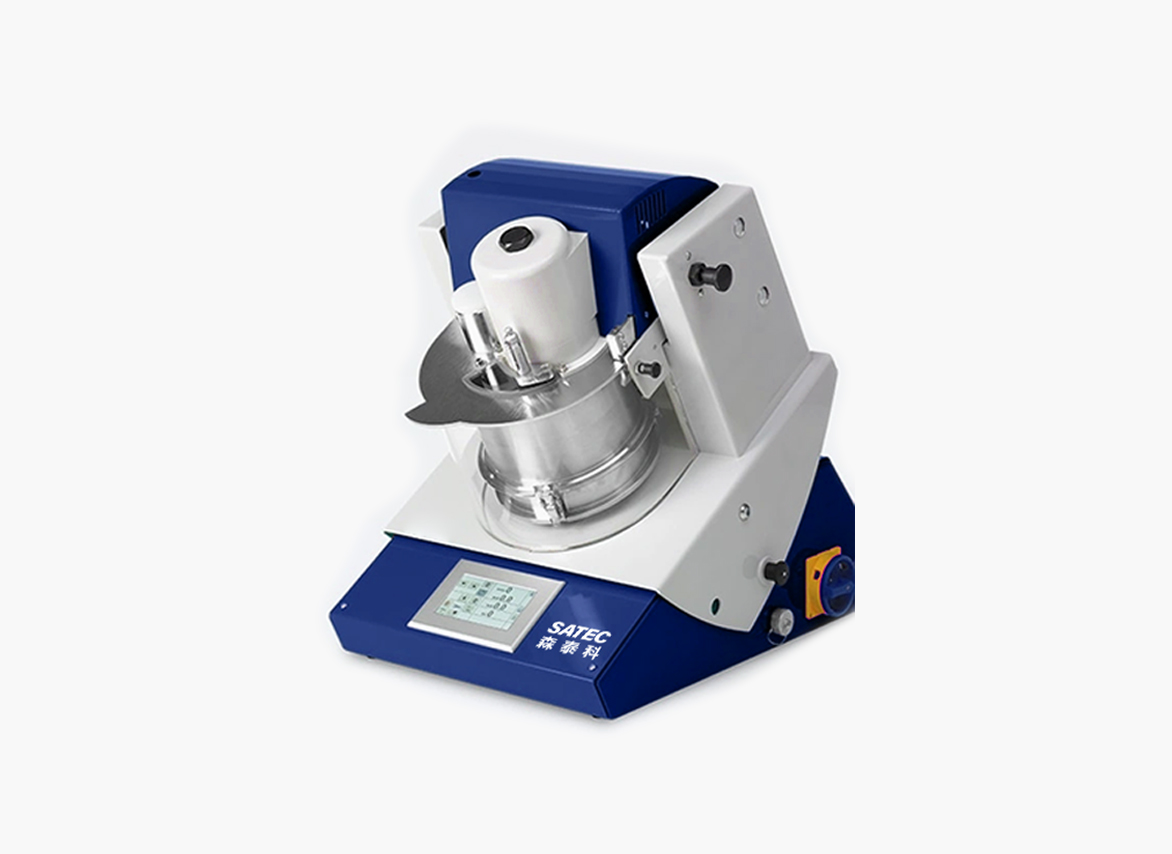

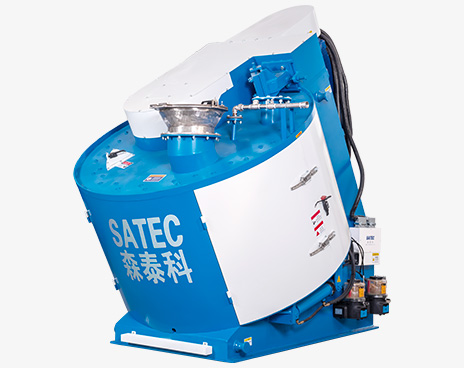

SATEC's unique intensive mixer

Our intensive mixer utilizes the countercurrent mixing principle to achieve optimal mixing uniformity in the shortest possible time.

Functions: Mixing, homogenizing, kneading, plasticizing, dispersing, granulating, agglomerating, emulsifying, coating, beating, pelletizing, etc.

Applications: Refractory materials, lithium batteries, ceramics, casting, metallurgy, environmental protection, building materials, chemicals, compound fertilizers

The figure below shows the volume loading capacity of a batch! The average mixing time is less than 1 minute, and the granulation time is completed within 3 minutes!

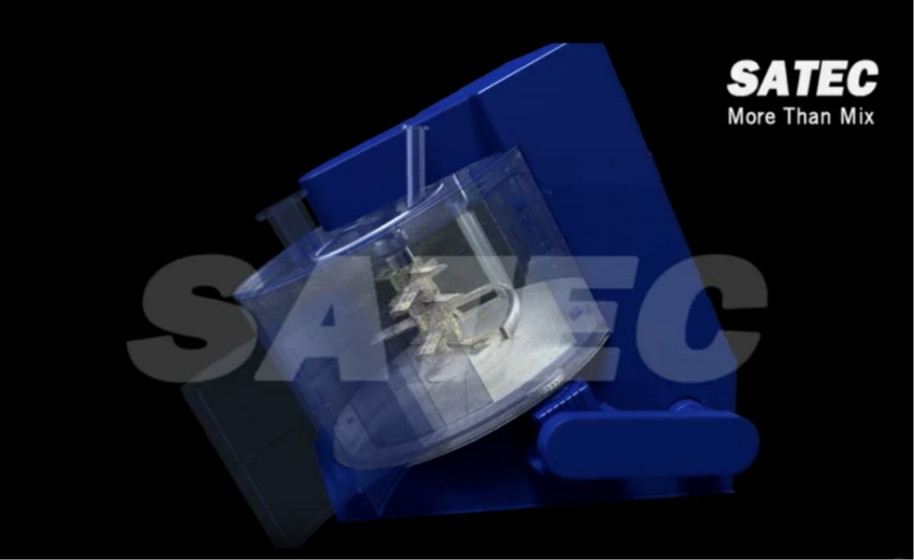

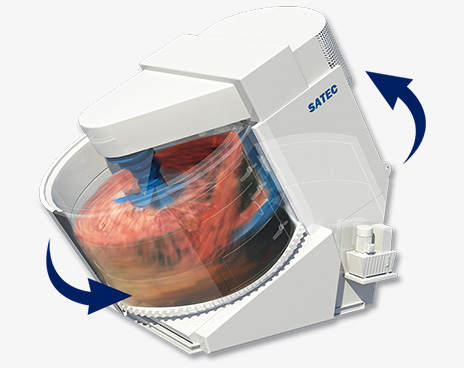

Mixing Principle

Under the combined action of high-speed rotor, rotating mixing pan and muti-function scraper, thebest mixing uniformity can be achieved in the shortest time.

Features

Efficient and stable mixing and homogenization

Utilizing the countercurrent mixing principle, the mixing tool, rotating pan, multi-function blade, and other components are scientifically designed and optimally configured to ensure optimal mixing uniformity in the shortest possible time.

Meets diverse material mixing requirements.

Proven mixing technology allows for individual component speed adjustments, making it widely applicable to material mixing. It not only homogenizes a variety of materials with varying particle sizes, but also meets the high mixing quality requirements of specific materials, improving process performance.

Adaptable to various installation locations.

Compact and modular, it occupies a small footprint and is easy to install and maintain, making it suitable for both new production lines and upgrades to existing ones.

parameter

| Model | Volume (L) | Weight (KG) | Discharge Method |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

C Series

| Model | Volume (L) | Weight (KG) | Discharge Method |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT25 | 1-6 | 10 | Manual Discharge |

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory