SATEC Testing Center

Meets material testing needs of global clients

After clients mail materials to us, SATEC can provide video recording or live streaming services in our laboratory.

We have extensive industry experience in mixing and granulation, and can provide formulation services for our clients!

Our laboratory offers rental services, catering to both research institutions conducting one-liter tests at a time and those requiring tests of thousands of liters!

We provide laboratory mixing equipment: laboratory mixers and laboratory granulators.

We offer leading domestic laboratory mixing and granulating machines.

We conduct thorough mixing tests on our clients' materials to meet their needs before putting them into production.

SATEC possesses unique professional technology and extensive experience in manufacturing, debugging, and mixing/granulating equipment.

Provide comprehensive pilot hybrid solutions for the following industries

Environmental protection industry

Lithium batteries

Catalyst

Pharmaceuticals and food

Metallurgical Pelletizing

Ceramics industry

Refractory materials

Carbon industry

Fertilizer industry

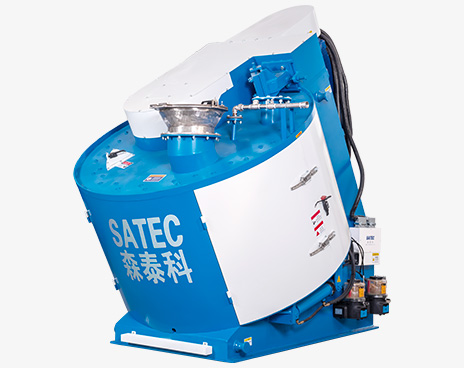

SATEC Intensive Mixer

Dispersion, granulation, pelletizing, kneading, heating, cooling, vacuuming, coating, emulsification, pulping, drying, reaction, mixing, wetting, coalescence, coating, etc.!

Suitable for research-oriented development and production to high standards.

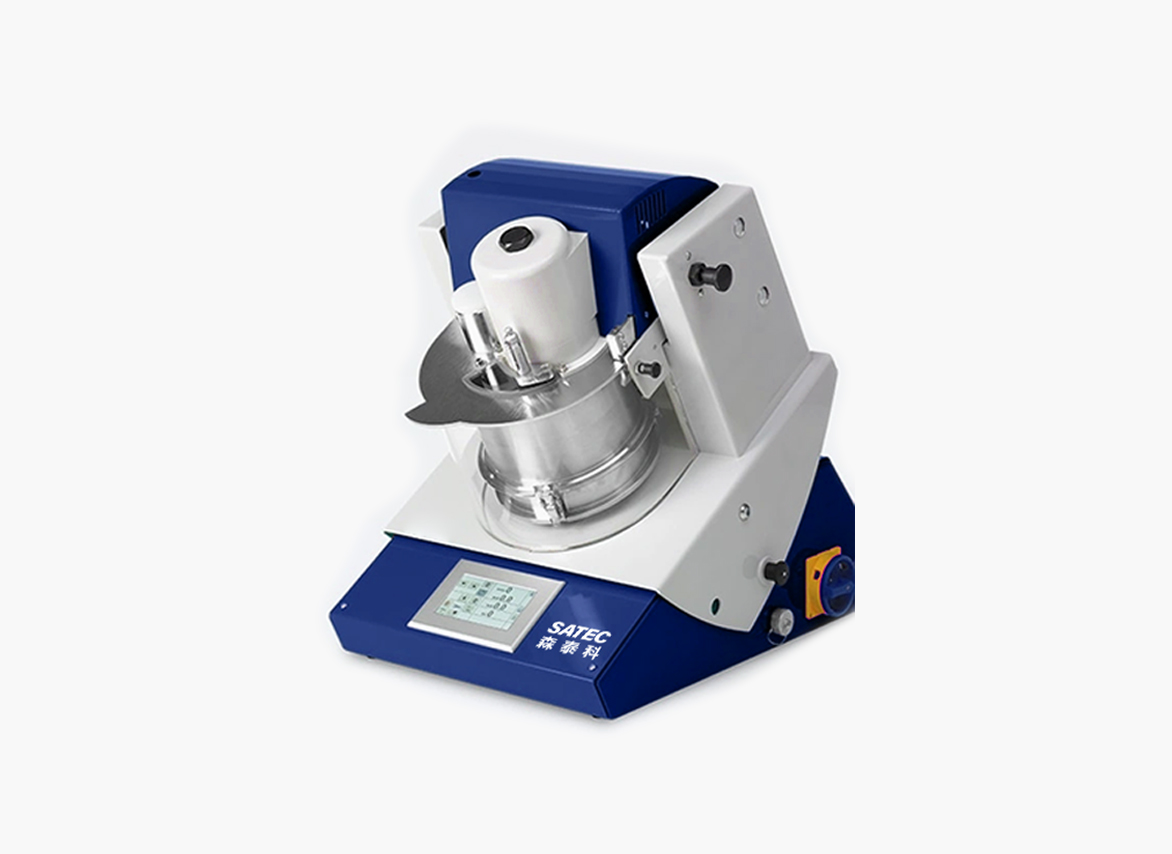

SATEC Laboratory Mixing Equipment

Flexible and high-efficiency mixing systems suitable for challenging tasks in research, development, and small-scale production.

Can process materials ranging from dry materials to plastics and pastes.

Applications:

The multi-functional mixing system can be used for a variety of applications such as mixing, granulation, coating, kneading, dispersing, dissolving, and fiber separation.

Scale-up testing results in industry is feasible.

Feeding:

Once the tool is retracted, raw materials and liquids are filled from above through a sealed, dustproof opening.

Employs state-of-the-art control technology

Features of Basic Equipment:

Mixing Pot: Stainless Steel

Mixing Tool: Star Rotor

Modular Layout: Made of Stainless Steel

Control System: Eco-friendly and Energy-saving

Processing Material Temperature: Maximum 200°C

Variations of hybrid tools

Pin rotor

Micronized rotor

Variations on wear protection available upon request

Other Options

Control System: Advanced Touch Control

Temperature Measurement of Inner Wall Scraper

Interchangeable Edges of Inner Wall Scraper, Optionally Made of PTFE, Polyamide, or Tungsten Carbide

Mixing Pan Made of Polyamide

Double-Layer Jacket Cooling

Mixer Inclination of 0° Supporting Fluid or Fluidized Materials

Roller Table with Adjustable Tilt for Flexible Base Frame

Function Funnel Made of Stainless Steel with Adapter for Adding Liquid

Heater (Hot Air), Including Temperature Measurement on Inner Scraper

Guidance and Training at Qingdao SATEC Testing Center 31

Advanced Touch Control

Rugged and durable stainless steel buttons integrated into the rack

Large 10-15 inch widescreen display within an aluminum housing, protected from dust and splashes

A tilt-adjustable monitor stand is available for use on a desktop next to the machine or as a control console version

User-friendly multi-touchscreen interface for easy preparation, performance, and recording of the mixing process

Customizable automated workflows based on time/temperature*/torque or energy, including individual steps of feed, sampling, and mixing.

Integrated measurement recording with multiple setting options

Batch archiving of process data and display of predefined, printable reports

Data export to USB media or network sharing in PDF, JPG, or text file format

Available interfaces: 1 USB, 1 Ethernet

Operating system: Windows 7

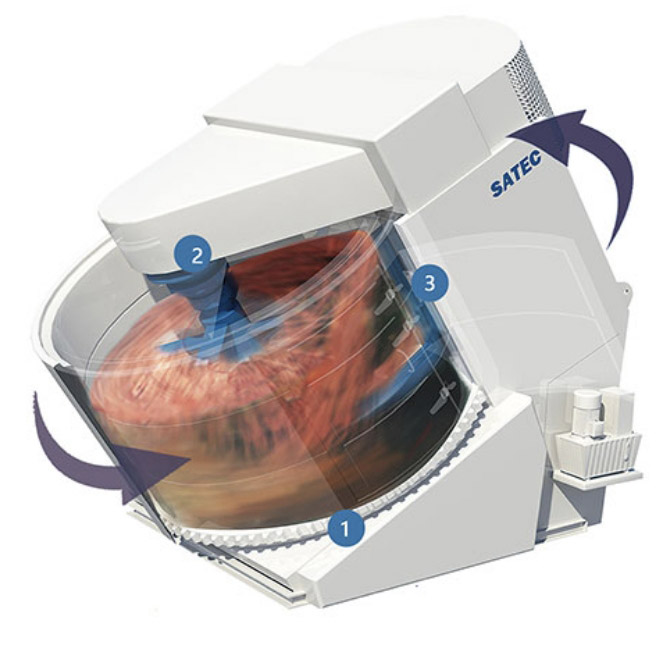

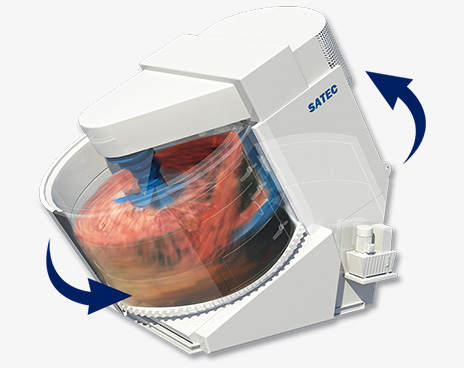

Turbulent Three-Dimensional Mixing Granulation Technology

Creating a new legend in industrial mixture preparation and granulation technology, starting with SATEC!

Mixing

Through the combined action of the high-speed rotor, granulation disc, and multi-functional scraper, the material is prepared into the required granules in the shortest possible time.

Mixing

A combination of rotary granulation and high-speed mixing granulation is used to complete pelletizing in the fastest and most efficient way.

Fixed

The mixing and granulation pan is installed at a specific angle, with a high-speed mixing and granulation tool set at the eccentric position, and an arc-shaped scraper installed at the bottom side of the pan.

Rotation

The granulation pan rotates clockwise at a low speed, conveying the material into the trajectory of the high-speed counter-clockwise rotating granulation tool assembly. Simultaneously, a fixed scraper disperses the material flow.

Speed

The rotational speed of the rotating pan and high-speed rotor can be preset according to process requirements; the speed of the integrated mixing and granulation machine can also be adjusted during the mixing and granulation process to achieve staggered mixing and granulation.

Nine key features worth having – core technological advantages

Uniform particle size

The process can be preset.

Particle size controllable

Easy to discharge

Full range of models

Meet the needs of all industries

Environmental friendly

Heated vacuum

Visual control system

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory