Chemical Industry

The manufacturing process of catalysts includes processes such as kneading, mixing, crushing, pulverizing, screening, slurry conveying, and granulation.

In the common operations of catalyst manufacturing, besides filtration, washing, and drying, there are also kneading, mixing, crushing, pulverizing, screening, and granulation.

Kneading, also known as mixing, is the continuous stirring of a paste or mud-like substance made by mixing different solid substances. The main purpose of kneading is to homogenize the different solid-liquid mixtures. To improve the homogeneity of the mixed precipitate, mixing is the process of uniformly distributing the particles of each component involved in the mixing under the action of external force, so that the proportion of each component in any small part of the mixed product is consistent with the formula. The speed of the mixer and the mixing equipment play a crucial role in the mixing of materials. When the speed of the mixer is insufficient, there is a problem of insufficient mixing of materials, and the various materials cannot be mixed evenly. The catalyst produced in this way is not very effective. If the speed is too high, there is a problem of adhesion for highly viscous materials, which are difficult to scrape off the inner wall of the mixer.

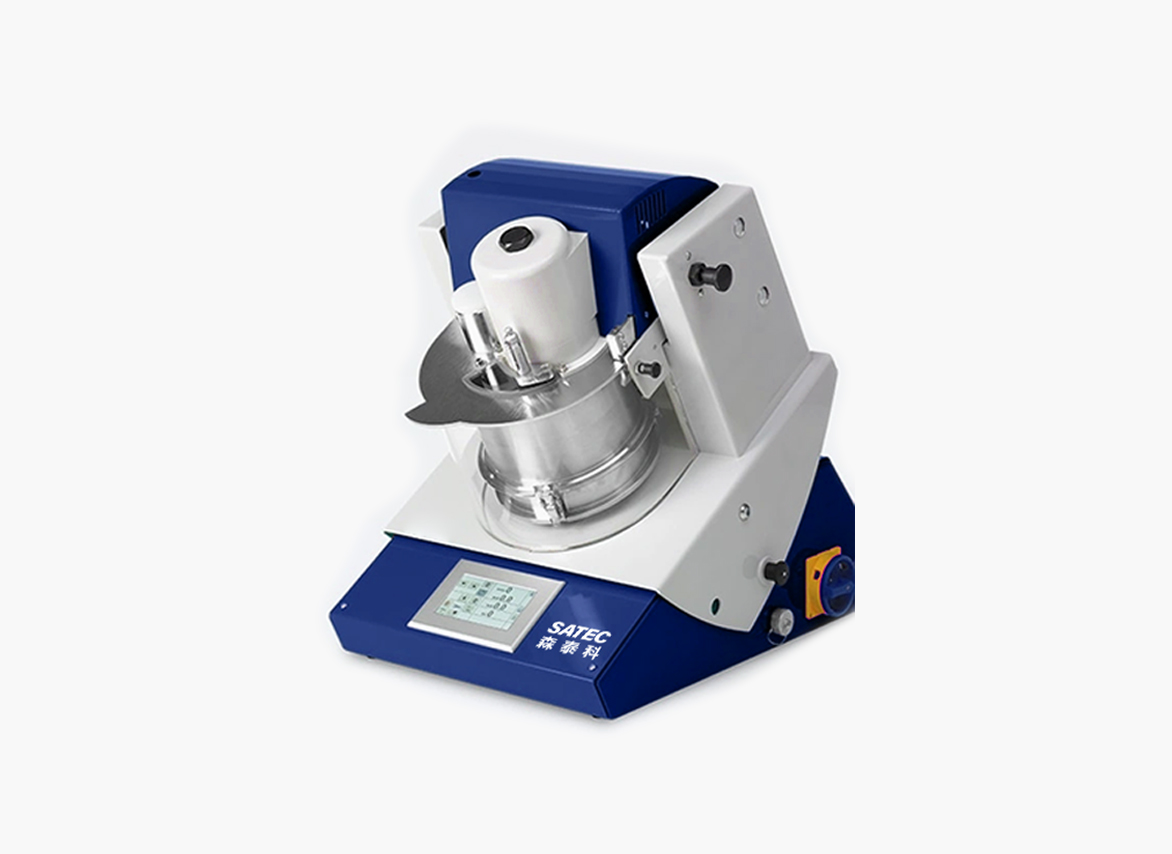

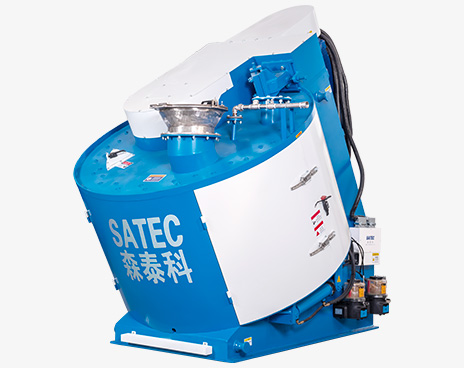

Qingdao SATEC Electro-Mechanical Technology Co., Ltd.'s mixing granulator is designed to meet the requirements of pellet production. The equipment is an inclined machine with an angle optimal for uniform material mixing, facilitating easy feeding and discharging and preventing excessive material accumulation in the pan. Its unique design allows for individual component speed adjustment, modifying the rotation speed according to the material's rotational requirements to achieve optimal mixing and avoid problems such as material buildup, poor mixing and granulation, and insufficient mixing and granulation due to excessive rotation speed. Its scientifically designed structure minimizes the need for maintenance and wear of parts, and the internal scraper ensures thorough material discharge. Compared to horizontal mixers, it offers significant advantages for discharging viscous materials.

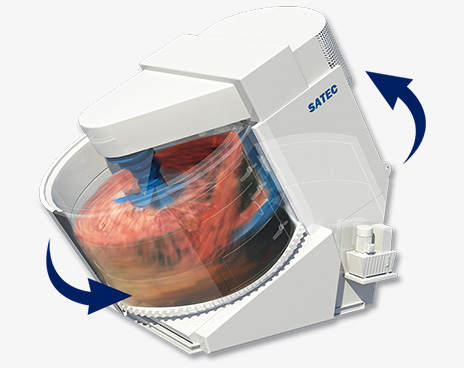

Granulation is the process of forming spherical particles from uniformly mixed materials through high-speed rotation. The diameter of the product varies depending on the rotational speed and centripetal force. Qingdao SATEC Electro-Mechanical Technology Co., Ltd.'s granulator utilizes the principle of turbulent three-dimensional mixing and granulation, performing mixing, kneading, and granulation within the same machine. The combined action of the high-speed rotor, granulation pan, and multi-functional scraper enables the production of the desired granules in the shortest possible time. During granulation, the rotational speed of the high-speed rotor in the rotating pan can be set according to process requirements. The speed of the running mixing granulator can also be adjusted during the mixing and granulation process to achieve a staggered mixing granulation process, thereby achieving the standard of thorough material mixing and granulation.

Qingdao SATEC Electro-Mechanical Technology Co., Ltd.'s mixers allow for individual adjustment of component speeds, improving mixing quality and material adaptability. The precise material residence time can be adjusted during the mixing process, and the mixer's rotational speed is adjustable, making it suitable for relatively fast-moving materials. Multi-dimensional mixing helps improve the uniformity of material mixing.

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory