Lithium-ion Batteries

Economical & Efficient - Time-Saving - Environmentally Friendly - Easy to Maintain

Innovative Technology in the Battery Industry

Highly efficient, economical, and environmentally friendly advanced battery manufacturing technologies are crucial factors in achieving high-quality standards in battery manufacturing systems.

After more than a decade of dedicated research and development, and close collaboration with the battery industry, SATEC is now able to provide companies with innovative and reliable technologies, along with comprehensive service guarantees.

One machine can complete raw material mixing, precision dispersion, compounding, granulation, surface treatment, and surface coating!

Equipment Features:

1. Improved performance of lithium battery positive and negative electrode materials

2. Improved performance of supercapacitors and lithium-ion capacitors

3. Improved dispersion and coating properties of electrode slurry (coating solution)

4. Improved battery performance through stirring of active materials, conductive agents, and solvent additives

5. Shorter mixing time for positive and negative electrode materials, reducing processing time by 1/10 compared to similar products

6. Minimal raw material residue within the chamber (side scraper)

7. High-speed rotating rotor improves dispersibility and enables rapid dispersion of high-viscosity liquids.

8.Surface treatment and coating enable efficient granulation and rapid dispersion of lightweight particles.

Application Areas

【Cathode Materials】Lithium cobalt oxide, lithium nickel oxide, lithium manganese oxide, lithium iron phosphate (NCA), NCM (ternary)

【Anode Materials】Lithium titanate, graphite, electronic materials, chemical materials, pharmaceuticals, food, cosmetics

Slurry Preparation

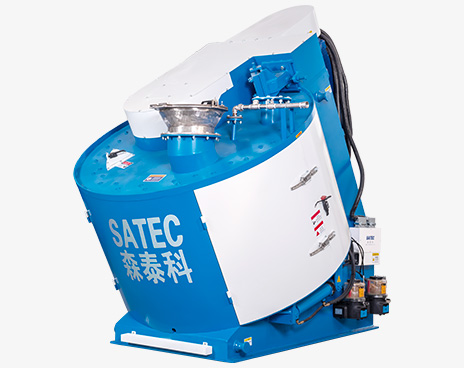

In the lithium battery industry, high-intensity mixers are commonly used for preparing slurries for cathode and anode materials, mixing electrolyte slurries, and surface coating of battery materials. Slurry preparation for cathode and anode materials is a crucial step in lithium battery production.

For preparing slurries for lithium battery cathode and anode materials, inclined high-intensity mixers are typically used. In this equipment, various raw materials such as lithium salts, polymers, and carbon black can be added and thoroughly mixed through intense friction and shear forces. Inclined high-intensity mixers are characterized by high mixing efficiency, low energy consumption, and ease of operation, significantly improving production efficiency.

Furthermore, intensive mixers are also essential equipment in the surface coating process of battery materials. Surface coating is typically performed using the sol-gel method, which involves coating the material surface with a layer of gel containing solid particles. Intensive mixers can thoroughly mix the coating and particles, resulting in a uniform coating with strong adhesion and excellent electrochemical performance.

In summary, intensive mixers are crucial equipment in the lithium-ion battery industry, providing efficient and precise support for the preparation and coating of battery materials.

Processing Technology

SATEC has improved lead paste preparation through its unique three-dimensional turbulent vacuum technology. SATEC optimizes equipment configuration based on customer needs using its modular system.

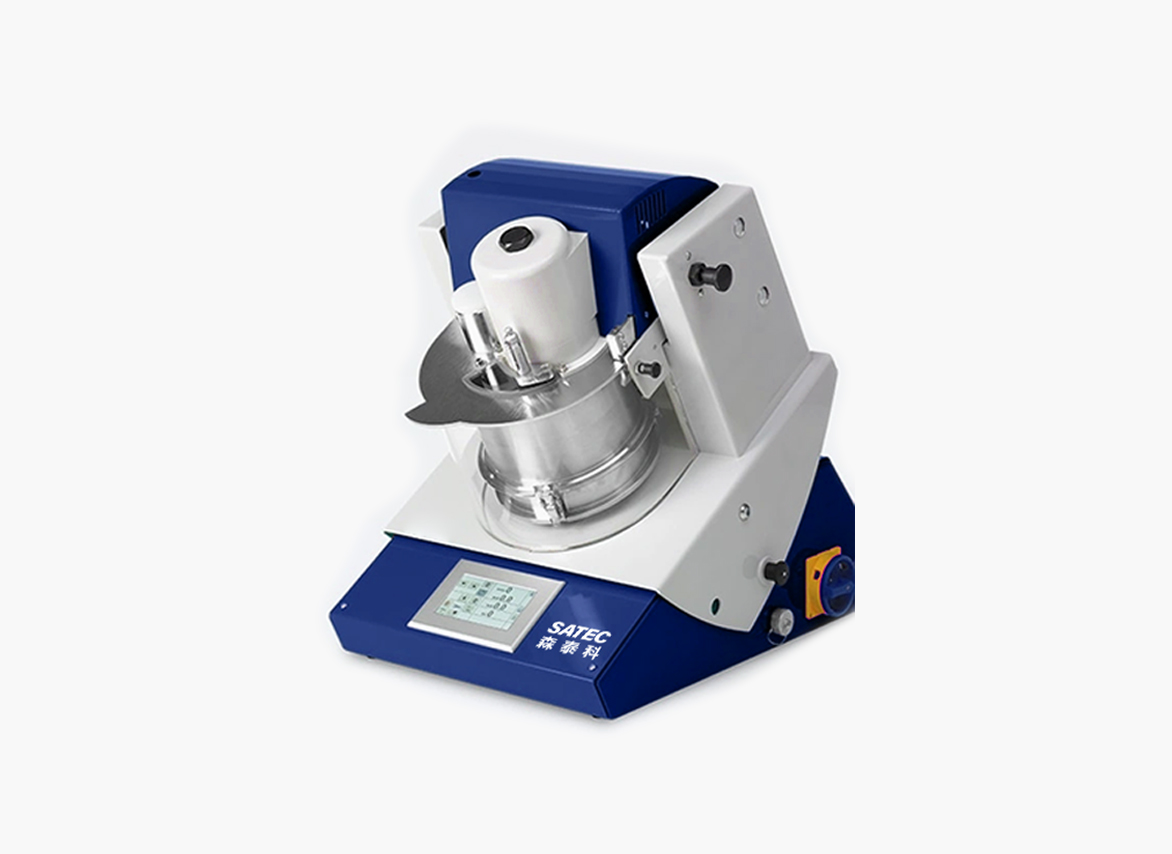

SATEC Lithium Battery Mixer:

The SATEC lithium battery mixer is a closed system with controllable mixing and reaction processes.

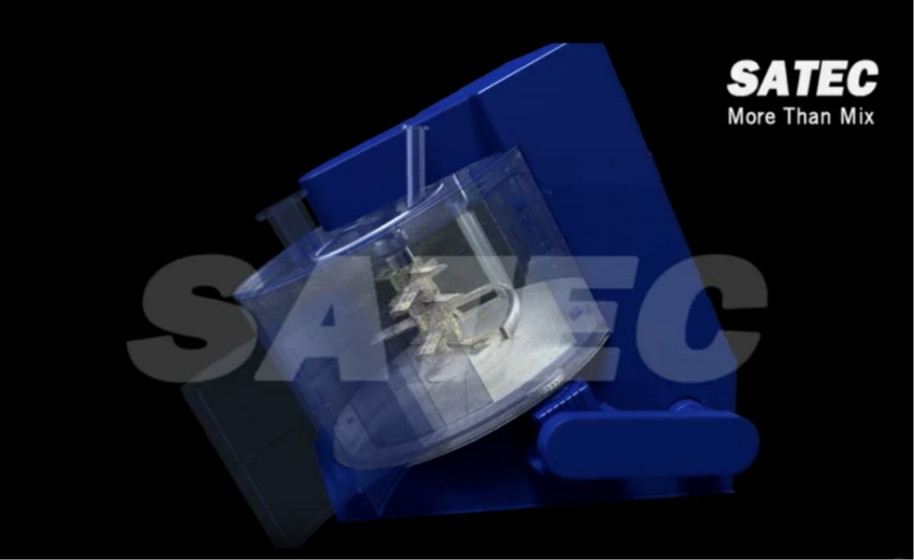

Mixing Principle

Excellent mixing results come from:

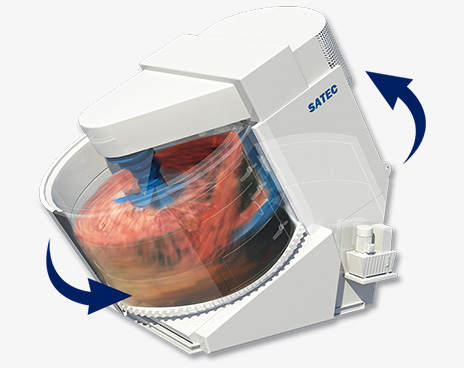

1. A rotating mixing pan, a high-speed rotating mixing tool that directly carries the material in centrifugal motion. This generates high-speed differential material flow.

2. An inclined rotating mixing pan. Connected to a fixed, dual-action wall scraper, ensuring significant vertical circulation of the material.

3. A dual-action wall scraper prevents material from sticking to the disc walls and bottom, and accelerates unloading at the end of the mixing cycle.

Reliable Technology, Safe Operation

Acids and additives are rapidly and uniformly dispersed:

SATEC's fully automatic penetration control, supported by vacuum technology, ensures consistent flowability. Meanwhile, the self-adjusting sealing of the discharge gate ensures optimal sealing protection for the mixing pan.

The following figure shows the volumetric loading capacity for a batch! Average mixing time is within 1 minute, and granulation is completed within 3 minutes!

Innovative preparation technology for lithium-ion batteries

Innovative Technologies in the Battery Industry

SATEC Lithium-ion Battery Mixer

High-efficiency, economical, and environmentally friendly advanced battery manufacturing technologies are crucial factors in achieving high-quality standards in battery manufacturing systems. The SATEC lithium-ion battery mixer is a closed system with controllable mixing and reaction processes.

Innovative Technologies in the Battery Industry

Excellent mixing results come from:

Reliable Technology and Safe Operation

Acids and additives are rapidly and uniformly dispersed. SATEC's fully automatic penetration control, supported by vacuum technology, ensures consistent flowability. Simultaneously, the self-adjusting seal of the unloading gate ensures optimal sealing protection for the mixing pan.

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory