The Use of Intensive Mixers in the Refractory Industry

For over a decade, SATEC has been a leading service provider of cutting-edge technology for refractory mixture preparation.

The final homogeneity and porosity of refractory materials are key factors determining their quality.

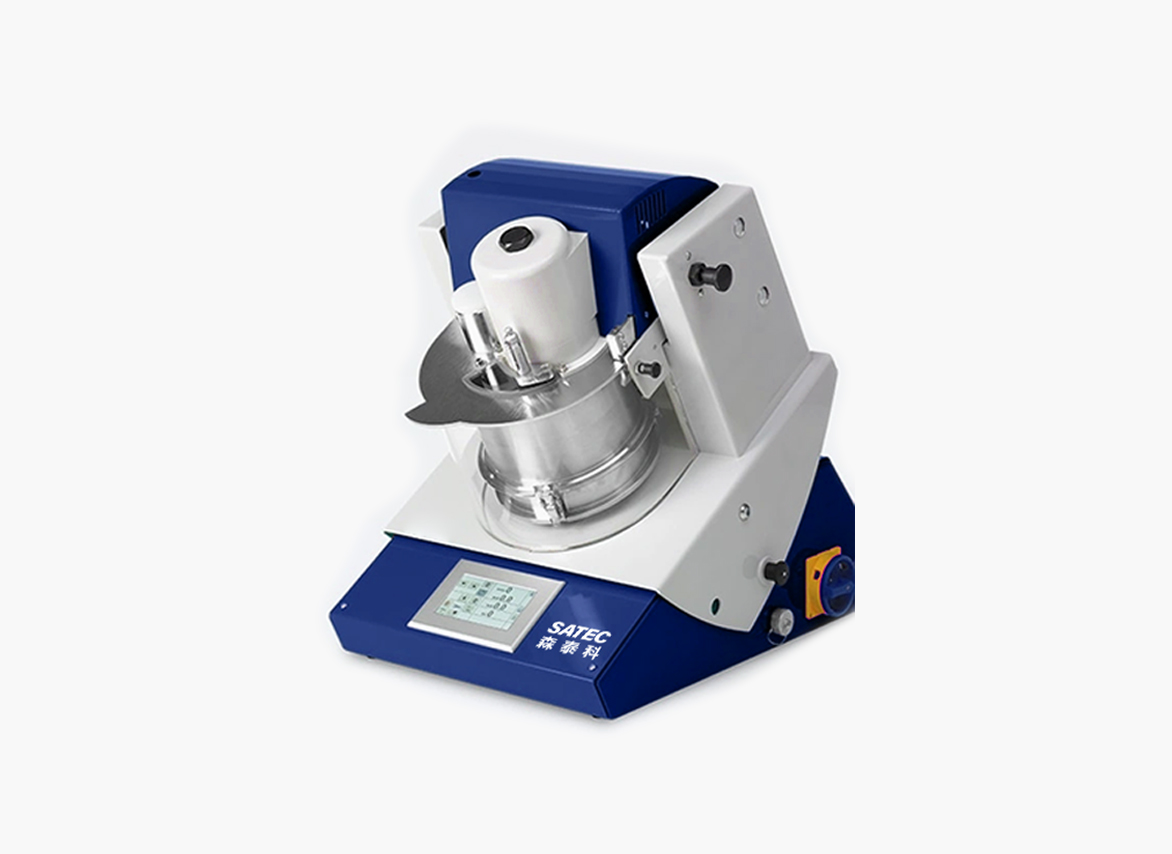

The revolutionary tilting mixer – a work of art among technological products.

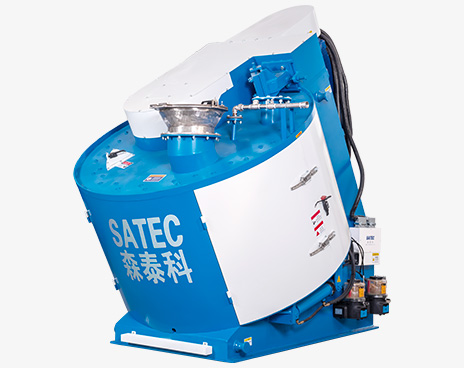

Currently, traditional vertical shaft mixers on the market cannot meet the high-precision and high-homogeneity mixing requirements of refractory materials, and can only meet the basic mixing and production needs of the refractory industry. In response to the high standards and stringent production demands of the current refractory market, traditional vertical shaft refractory mixing equipment is gradually being phased out. To meet the diverse and high-precision production needs of users in the refractory market, SATEC has launched a special inclined refractory mixer. In 2023, SATEC's inclined refractory mixer will replace traditional vertical shaft refractory mixing equipment.

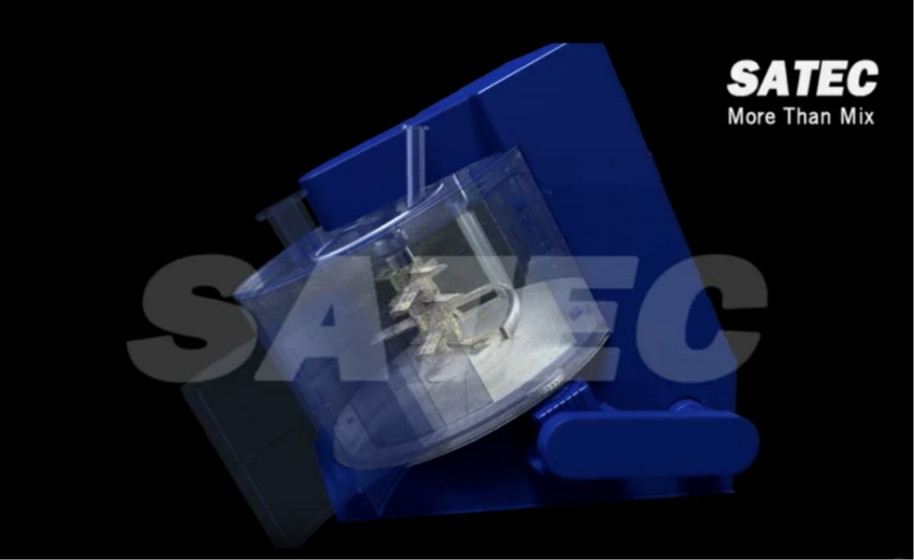

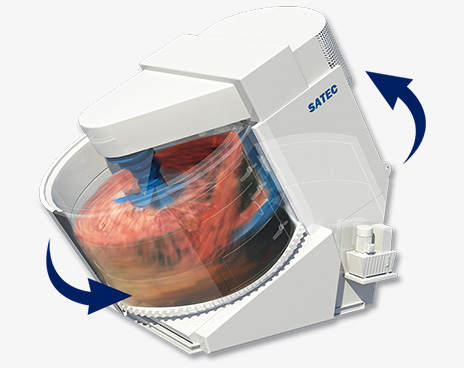

Compared to traditional vertical shaft mixers, the inclined refractory mixer utilizes our unique three-dimensional turbulent mixing technology. This results in a larger internal space within the mixing pan, more uniform material mixing, shorter mixing time, and higher efficiency. There are no dead zones during the entire mixing process. The speed is adjustable at any time, and the controllable LED operation panel simplifies operation. Hydraulic unloading is faster, the structural device has more stable transmission, and the wear-resistant lining reduces wear rate, extends service life, minimizes material residue in the pan, and minimizes material porosity, improving product quality and increasing profitability.

Intensive Refractory Material Mixer

Providing customers with a one-stop solution for mixing and granulation

From material mixing and granulation equipment, batching systems, and panel control technology systems, to even the entire production line.

We offer domestically leading laboratory mixing and granulation machines to conduct thorough mixing tests on customer materials, ensuring they meet customer needs before production. SATEC possesses unique professional technology and extensive experience in manufacturing and debugging mixing and granulation equipment.

In the refractory materials industry, SATEC's mixing and granulation machines offer professional technical support and industry experience.

Refractory Porosity

SATEC's inclined intensive refractory mixer allows for individual speed adjustments of components, improving mixing quality and material adaptability. During the mixing process, it precisely adjusts material residence time and rotor speed. Its unique three-dimensional turbulent mixing technology maximizes material uniformity, reduces material residue in the pan, and minimizes material porosity. It is a powerful and efficient mixing device specifically designed for high precision and homogenization in refractory production.

Factors Affecting Billet Mixing - Mixing Quality and Uniformity

It can meet the requirements of various refractory mixing processes, allows for individual adjustment of component speeds to improve mixing quality and material adaptability, and enables precise adjustment of material residence time during mixing. It is suitable for relatively fast-moving materials, and multi-dimensional mixing can improve the uniformity of material mixing.

◎Shaped Refractory Materials: ☑ Fired Products ☑ Unfired Products

◎Unshaped Refractory Materials: ☑ Castables ☑ Spray Paints ☑ Ramming Mixes ☑ Plastics ☑ Projectiles ☑ Coatings ☑ Dry Vibrating Mixes ☑ Self-flowing Castables ☑ Refractory Slurries

The following figure shows the volumetric loading capacity for a batch! Average mixing time is within 1 minute, and granulation is completed within 3 minutes!

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory