Granulation Technology

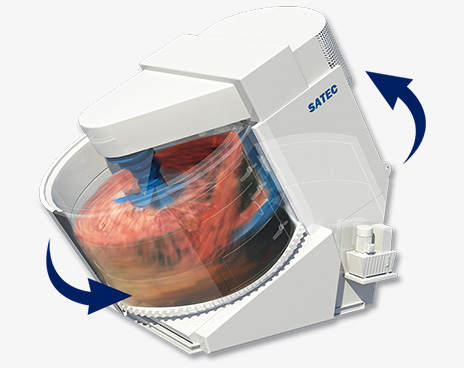

SATEC's Leading Mixing and Granulating Technology

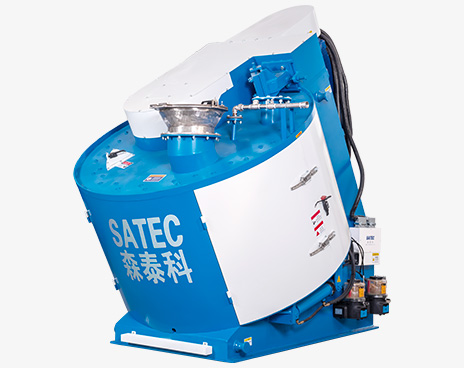

In SATEC's extensive granulation trials, materials are typically granulated within the drum within 3 minutes!

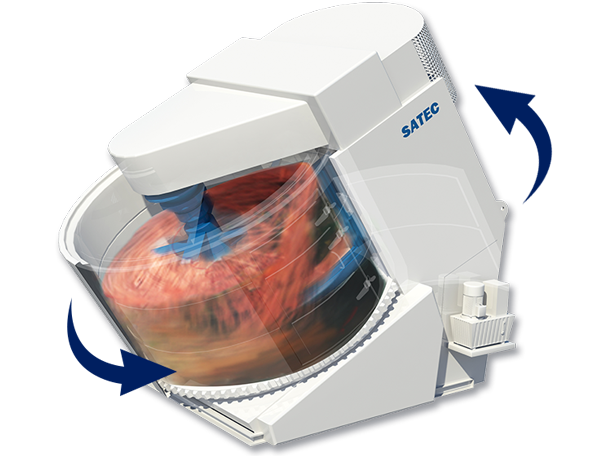

Our designed mixing and granulating machine combines mixing and granulation within a single unit, significantly reducing production costs and energy consumption, and shortening the return on investment.

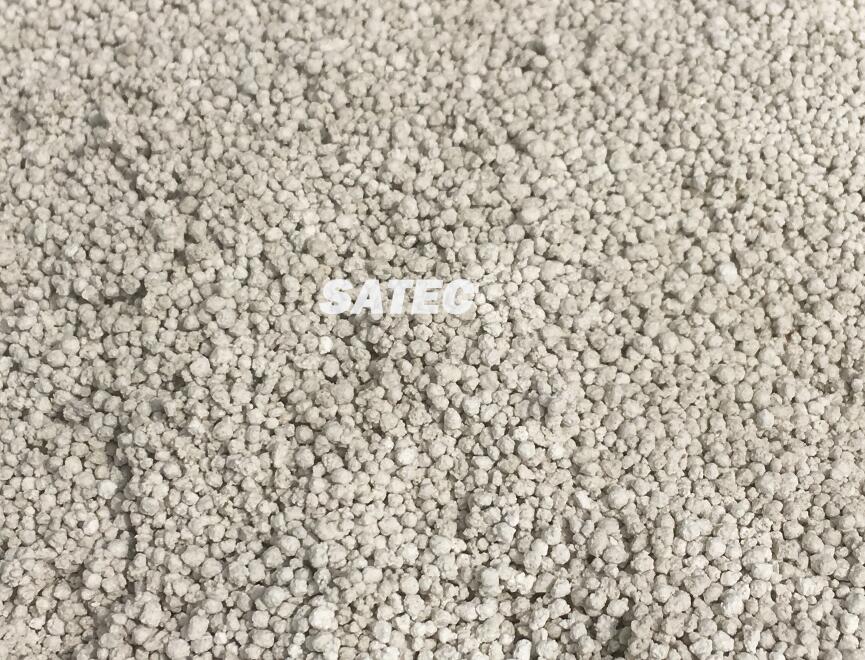

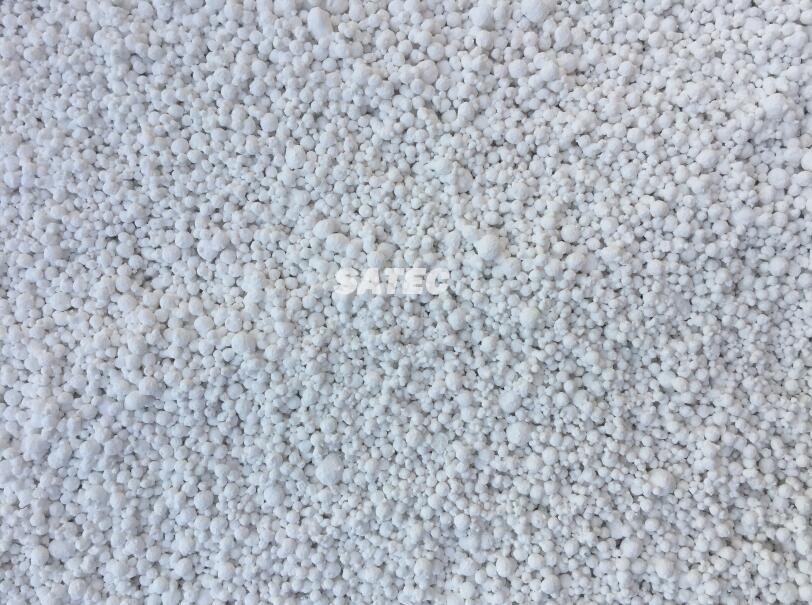

The desired particle size and distribution can be achieved by adjusting the rotor and mixing pan speeds, resulting in highly stable agglomerates and granules.

Its main advantages are:

◎ Energy saving ◎ Improved particle density ◎ Better particle shape ◎ Online particle size adjustment

Application industries

Ceramics: Molecular sieves, proppants, abrasives, grinding balls, ferrites, and oxide ceramics

Environmental protection: Fly ash, ash slag, dust, sludge, etc.

Chemicals: Fertilizers, phosphate fertilizers, mineral materials, lime, carbon black, etc.

Building materials: Refractory ceramsite, clay ceramsite, shale ceramsite, ceramsite filter media, ceramsite bricks, ceramsite concrete, etc.

Glass: Glass powder, waste glass slag

Metallurgy: Iron ore, zinc ore, lead ore, alumina, etc.

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory