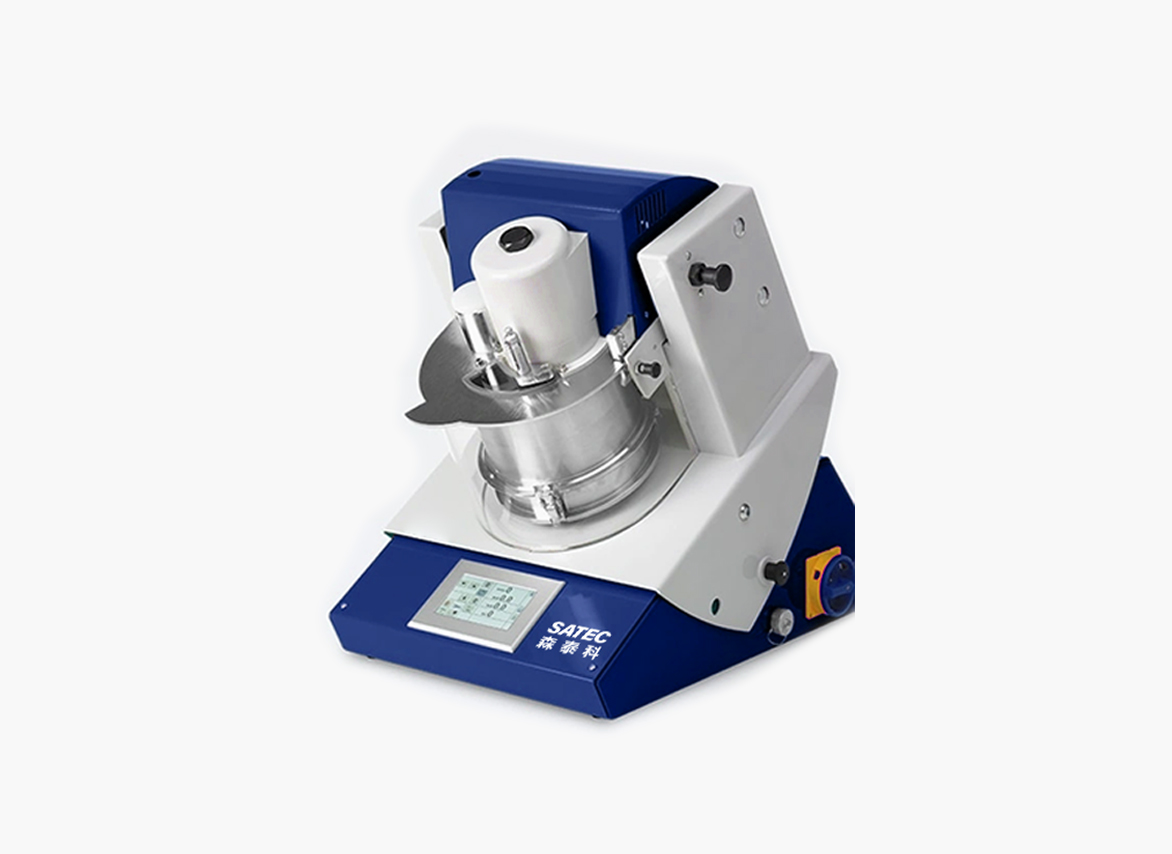

Mixing and Granulating Machine

SATEC's unique and leading mixing and granulating technology

The efficiency of intensive mixer is primarily measured by mixing uniformity and time.

Qingdao SATEC Electro-Mechanical Technology Co., Ltd.'s intensive mixing and pelletizing machine utilizes the principle of turbulent mixing and granulating, completing mixing, kneading, and pelletizing in a single device. With minimal steps and simple operation, it can quickly and efficiently produce the desired granules in the shortest possible time.

High pelletizing rate, uniform granule size, fine granule shape, and high strength.

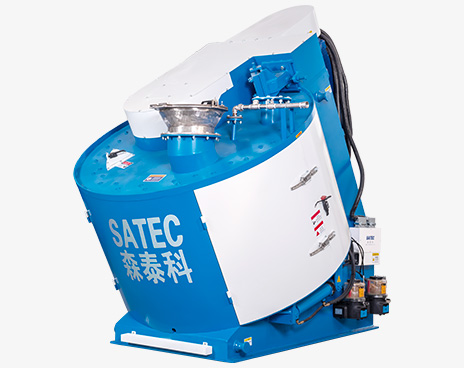

The rotating mixing pan and pelletizing tool assembly are variable frequency controlled with adjustable speed, allowing for controlled granule size.

Discharging options include tilting or bottom discharge (hydraulic control), ensuring fast, clean, and easy cleaning.

A comprehensive range of models is available, meeting needs from small-scale laboratory granulation to large-scale industrial pelletizing.

A wide range of applications caters to the mixing needs of various industries and materials.

The figure below shows the volume loading capacity of a batch! The average mixing time is less than 1 minute, and the granulation time is completed within 3 minutes!

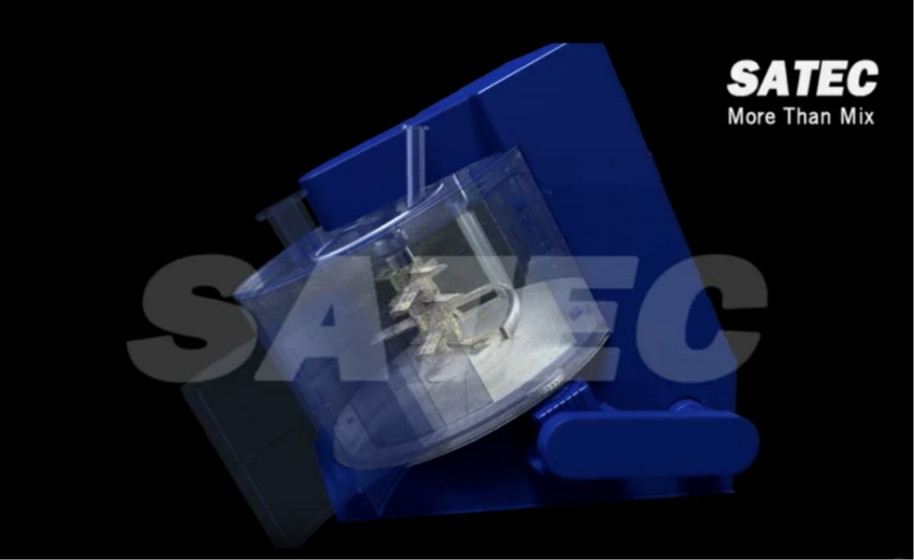

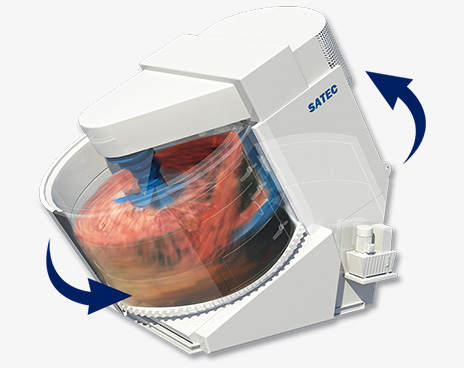

Principle of granulation

◎ Utilizing the principle of counter-current three-dimensional motion, this system combines rotary granulation and high-speed mixing granulation to achieve pelletizing in the fastest and most efficient manner.

◎ The main functional components consist of a mixing and granulation pan, a high-speed mixing and granulation tool assembly, and a fixed scraper. The mixing and granulation pan is installed at a specific angle, with the high-speed mixing and granulation tool assembly located at an eccentric position, and the fixed arc-shaped scraper installed at the bottom side of the pan.

◎ During the granulation process, the granulation pan rotates clockwise at a low speed, while the granulation tool assembly rotates counter-clockwise at high speed. The rotating granulation pan conveys the material into the trajectory of the granulation tool assembly, while the fixed scraper disperses the material flow. Under the combined action of the rotating pan, the high-speed granulation tool assembly, and the fixed scraper, a complex three-dimensional mixing and granulation material flow is formed, achieving rapid and high-quality homogenization of the material and simultaneously completing pelletizing.

Features

◎ Mixing, kneading, and granulation are completed in a single machine, resulting in fewer steps, simpler operation, and a shorter process flow.

◎ Particle size and strength can be controlled by adjusting the rotation speed and time; particle size can be freely adjusted as needed.

◎ Wide range of operating conditions and applicable industries; suitable for pelletizing in various industries, producing high particle formation rate, good particle shape, and high strength.

◎ No dead zones in mixing and granulation; all materials are fully involved in granulation, ensuring complete mixing and uniform particle size.

◎ The entire mixing and granulation process is carried out in a fully sealed environment, eliminating dust pollution and ensuring a clean and environmentally friendly working environment.

◎ Unloading is achieved using both tilting discharge (small model) and hydraulic center discharge methods, ensuring fast and clean unloading and easy cleaning.

◎ Compact structure, reasonable design, small footprint, and easy installation and maintenance.

◎ The granulation tool assembly has two structures: multi-layer rotor blade assembly and pin granulation disc, allowing for optimal selection based on material properties and granulation purpose.

◎ Both the granulation tool set and the scraper undergo special wear-resistant treatment, ensuring a long service life and easy replacement.

◎ The installation angle, shape, rotation speed, and time of the granulation tool set can be adjusted as needed according to material properties to prepare the desired granules.

◎ Equipped with an independent control cabinet, it can be connected to a PLC touchscreen control system, enabling both automatic and manual operation.

◎ Heating and vacuum functions can be added upon user request.

◎ The installation angle, shape, rotation speed, and time of the granulation tool set can be adjusted as needed according to material properties to prepare the desired granules.

◎ Equipped with an independent control cabinet, it can be connected to a PLC touchscreen control system, enabling both automatic and manual operation.

◎ Heating and vacuum functions can be added upon user request.

parameter

| Model | Volume (L) | Weight (KG) | Discharge Method |

| SIMT25 | 1-6 | 10 | Manual Discharge |

| SIMT35 | 8-10 | 20 | Tilting Discharge |

| SIMT55 | 15-40 | 65 | Tilting Discharge |

| SIMT80 | 150 | 120 | Tilting Discharge |

| SIMT90 | 250-375 | 240 | Hydraulic Center Discharge |

| SIMT110 | 250-400 | 400-600 | Hydraulic Center Discharge |

| SIMT125 | 250-400 | 400-650 | Hydraulic Center Discharge |

| SIMT150 | 500-750 | 800-1200 | Hydraulic Center Discharge |

| SIMT160 | 600-900 | 960-1440 | Hydraulic Center Discharge |

| SIMT180 | 800 | 950 | Hydraulic Center Discharge |

| SIMT190 | 1125-1500 | 1800-2400 | Hydraulic Center Discharge |

| SIMT220 | 2000 | 3000 | Hydraulic Center Discharge |

| SIMT240 | 2250-3000 | 3600-4800 | Hydraulic Center Discharge |

| SIMT280 | 4000-5500 | 6400-8800 | Hydraulic Center Discharge |

| SIMT320 | 5250-7000 | 8400-11200 | Hydraulic Center Discharge |

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory