Mixers and Granulators for the Ceramic Industry

Leading Mixing and Granulation Technology in the Ceramic Industry

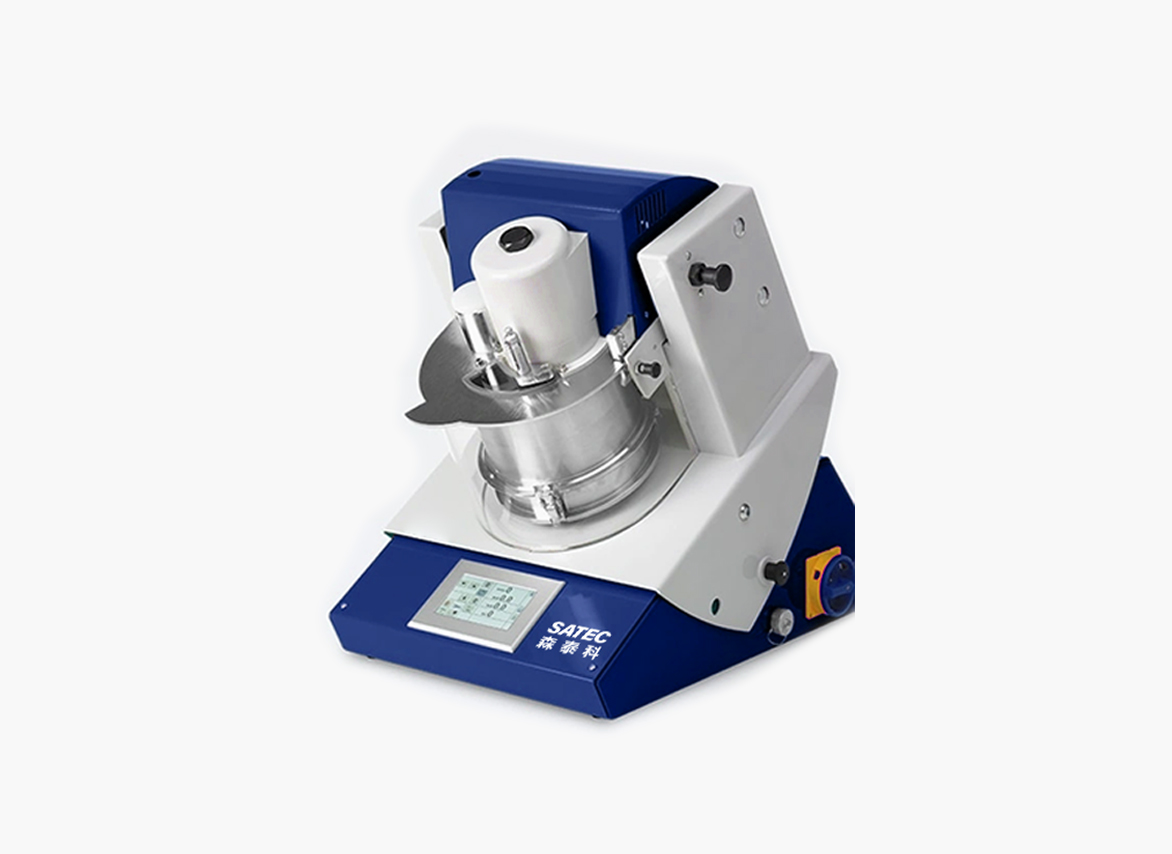

SATEC is a leading service provider in mixing and granulation for the ceramic industry.

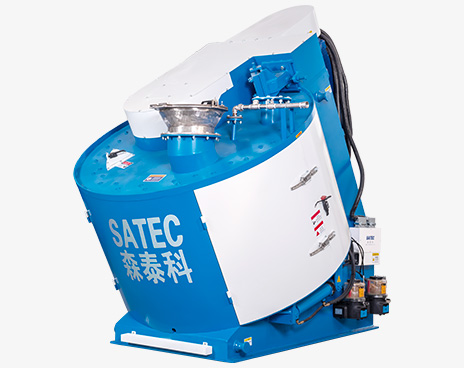

SATEC's ceramic industry granulators uniformly mix powder and binder in an internal mixer, creating tiny particles under centrifugal force and high-speed rotation.

◎ Suitable for processing viscous materials;

◎ Stable product quality, high level of automation, and large production capacity;

◎ Uniform particles, good strength, and high granulation rate;

◎ High degree of automation, continuous production capability, high production efficiency, and low dust pollution;

◎ Prevents re-agglomeration and sedimentation separation of components in the slurry, maintaining the original uniformity of the slurry and resulting in uniform particle size distribution, good flowability, and high-quality green powder;

◎ Regular particle shape, which helps improve the density and uniformity of green bodies, thereby improving the sintering performance of green bodies.

Mixing is the process, under the action of external force, to uniformly distribute the particles of each component involved in the mixing, ensuring that the proportion of each component in any tiny volume of the finished mixture matches the formula.

Mixers are classified into batch mixers and continuous mixers based on the continuity of the mixing process, and into vertical mixers and horizontal mixers based on the arrangement of their working parts. Generally, the residual rate of material in the mixer decreases as the rotor working gap decreases and increases as the rotor diameter increases. Reducing the residual rate is achievable through the design of a reasonable rotor working gap in the mixer.

Comparison of mixers in the ceramic industry market:

Horizontal mixers are less effective at mixing highly viscous substances. They cannot fully discharge the material.

The advantages of a vertical mixer are: low power consumption (approximately 1.75kW for a 1t capacity mixer); small footprint; can be used as a standalone unit; structurally, the low inlet position reduces material lifting, allowing for both mixing and serving as a finished product storage area; it can also be used in conjunction with other equipment (such as other mixers).

The disadvantages are: long mixing time and low production efficiency; mixing quality is greatly affected by the feeding sequence; and high residue levels.

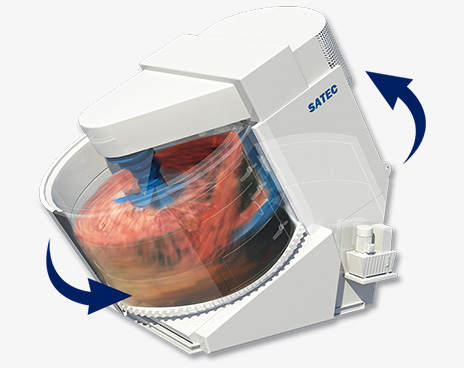

SATEC ceramic industry mixers allow for individual component speed adjustments, improving mixing quality and material adaptability. Accurate material residence time can be adjusted during mixing, and the mixer's speed is adjustable, making it suitable for relatively fast-moving materials. Multi-dimensional mixing helps improve material uniformity and reduce residue levels.

Suitable for:

◎Daily-use ceramics ◎Building and sanitary ware ceramics ◎Chemical ceramics ◎Electrical porcelain ◎Specialty ceramics

The following figure shows the volumetric loading capacity for a batch! Average mixing time is within 1 minute, and granulation is completed within 3 minutes!

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory