SATEC

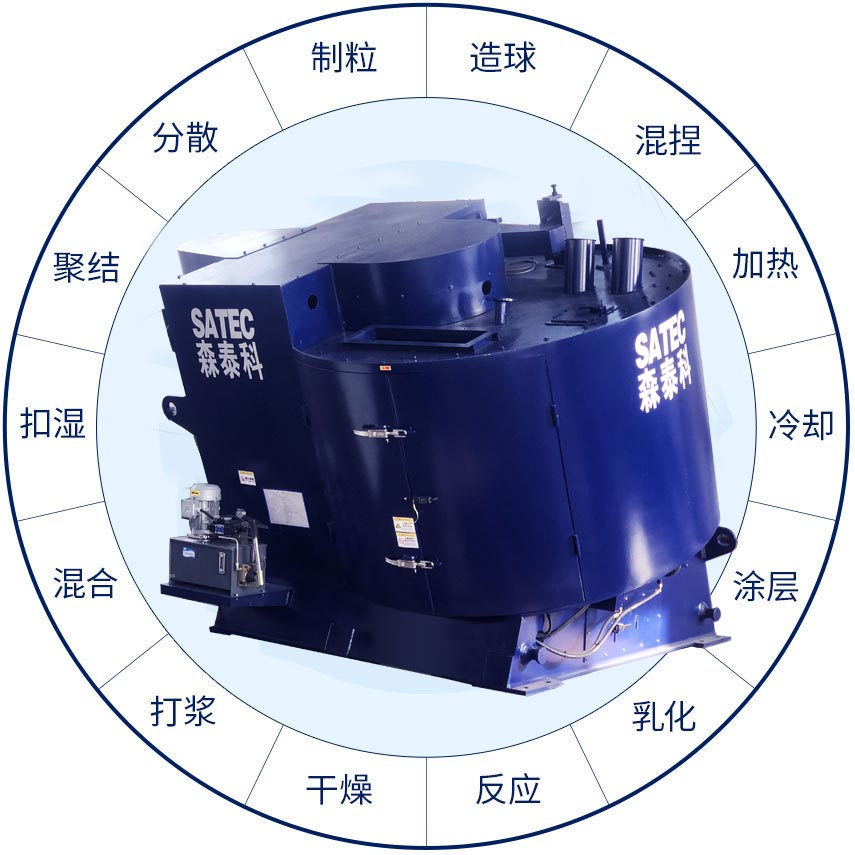

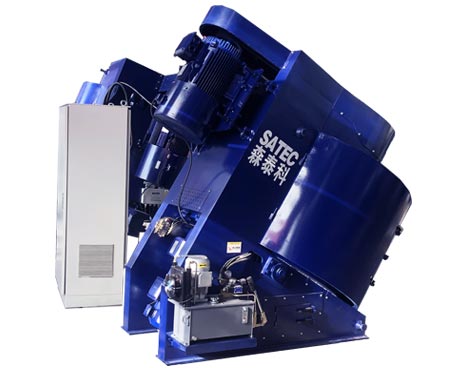

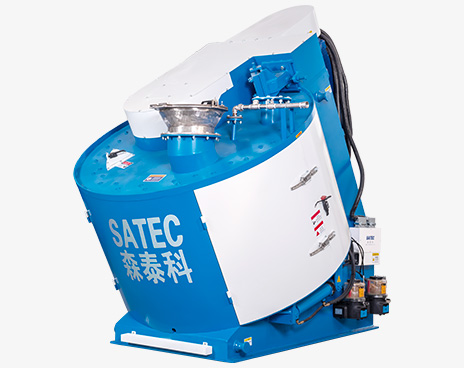

SATEC, a leading brand of mixing granulators in China, primarily manufactures industrial mixing granulators and intensive mixers. SATEC boasts its own R&D team and advanced production base, providing customized one-stop plant design solutions to meet the diverse material and site requirements of its clients. Its main products, mixing granulators, serve multiple industries including refractory materials, glass, ceramics, chemicals, and foundry sand, and have obtained numerous patents. Choose SATEC for your mixing granulator needs! Because we are more professional!

SATEC has focused on mixing and granulation for 10 years,

creating a new legend in industrial mixture preparation and granulation technology, starting with SATEC!

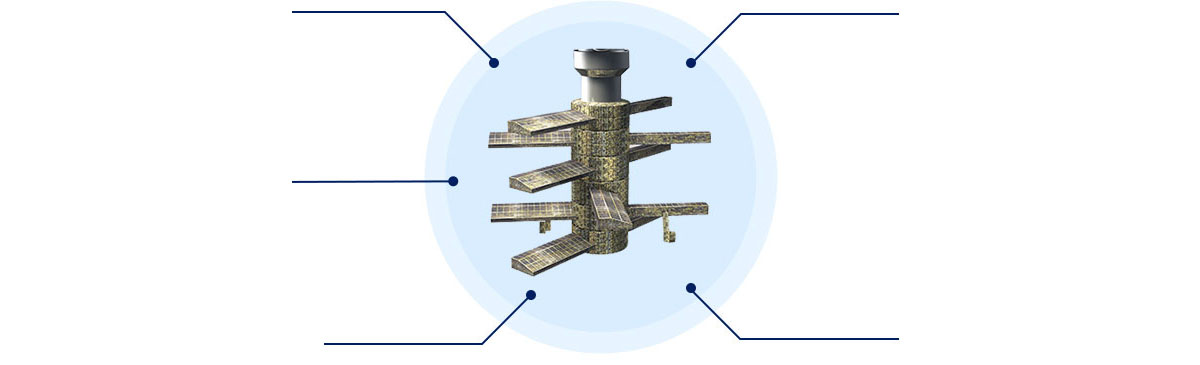

Turbulent Three-Dimensional Mixing Granulation Technology

SATEC is an ideal equipment for the mixing and preparation of powder and fine particulate materials.

-

Enhanced

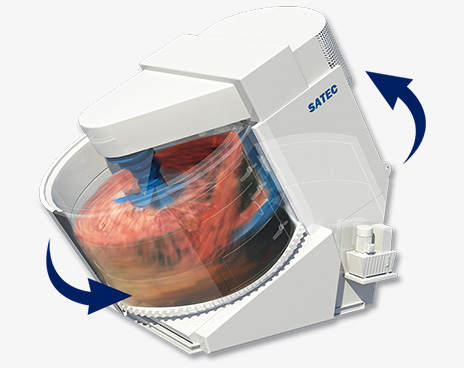

Turbulent three-dimensional mixing and granulation technology: Enables the completion of mixing, kneading, pelletizing and granulation processes within the same equipment, ensuring that the mixture is fully homogeneous.

-

Faster

SATEC's proprietary turbulent three-dimensional mixing granulation technology saves at least three times the time compared to other granulators on the market!

-

More uniform

Fewer steps, simpler operation, and can quickly and efficiently produce the required particles in the shortest possible time.

Turbulent 3D Mixing Granulation Technology: Creating an Industry-Leading Brand.

Creating a new legend in industrial mixture preparation and granulation technology, starting with SATEC!

-

Mixing

Mixing

Through the combined action of the high-speed rotor, granulation pan, and multi-functional scraper, the material is prepared into the required granular material in the shortest possible time.

-

Mixing

Mixing

A combination of rotary granulation and high-speed mixing granulation is used to complete pelletizing in the fastest and most efficient way.

-

Fixed

Fixed

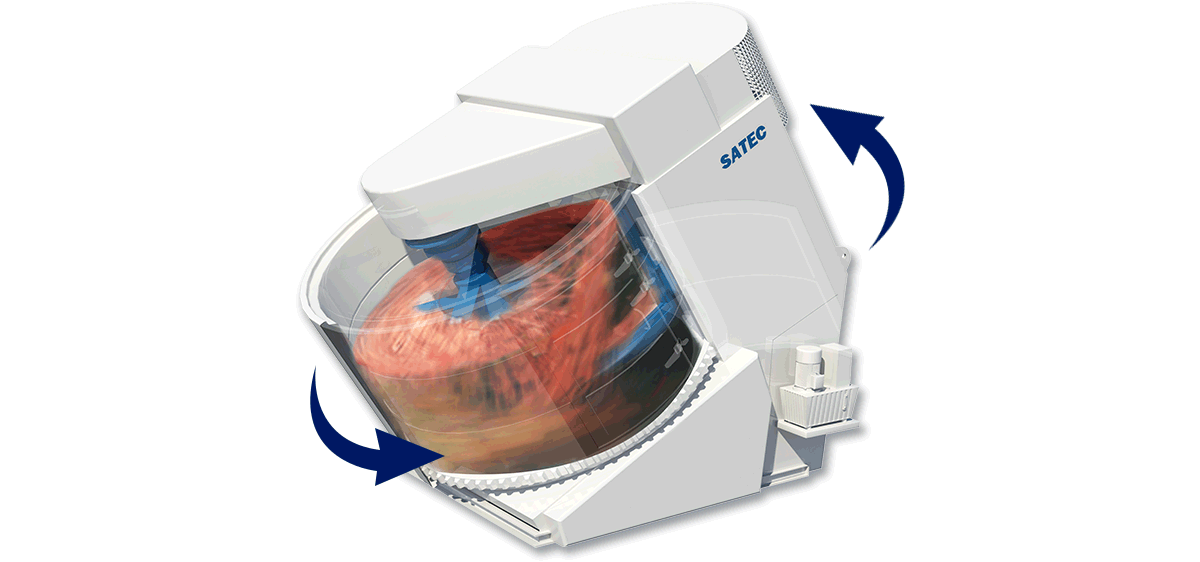

The main functional components consist of a mixing and granulation pan, a high-speed mixing and granulation tool set, and a fixed scraper; the mixing and granulation pan is installed at a specific angle, with the high-speed mixing and granulation tool set located at an eccentric position, and the fixed arc-shaped scraper installed at the bottom side of the pan.

-

Rotation

Rotation

During the granulation process, the granulation pan rotates clockwise at a low speed, while the granulation tool assembly rotates counterclockwise at a high speed. The rotating granulation pan conveys the material into the trajectory of the granulation tool assembly, while a fixed scraper disperses the material flow. Under the combined action of the rotating granulation pan, the high-speed granulation tool assembly, and the fixed scraper, a complex three-dimensional mixed granulation material flow is formed, achieving rapid and high-quality homogenization of the material and simultaneously completing pelletizing. The rotor can also be configured to rotate in the same direction.

-

Speed

Speed

During granulation, the rotation speed of the rotating pan and high-speed rotor can be preset according to process requirements; the speed of the integrated mixing and granulation machine can also be adjusted during the mixing and granulation process to achieve staggered mixing and granulation.

Nine key features worth having – core technological advantages

A new concept in "turbulent three-dimensional mixing granulation technology"

-

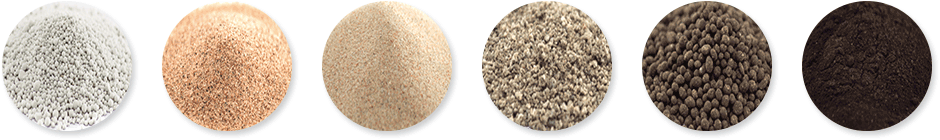

01Uniform Particle Size

High pelletizing rate, uniform particle size, and high strength.

-

02Presettable Process

The mixing and granulation process can be preset and adjusted during production.

-

03Controllable Particle Size

The rotary mixing pan and granulation tool assembly are frequency-controlled, and the rotation speed is adjustable, allowing control over particle size.

-

04Convenient Discharge

Discharge methods include tilting discharge or bottom discharge (hydraulic control), ensuring quick and clean discharge and easy cleaning.

-

05Complete Model Range

A complete range of models, from small-scale laboratory granulation to large-scale industrial pelletizing, to meet all needs.

-

06Suitable for Various Industries

Widely applicable, meeting the mixing needs of different industries and various materials.

-

07Environmentally Friendly

The entire mixing and granulation process is carried out in a fully enclosed manner, with no dust pollution, ensuring safety and environmental protection.

-

08Heating/Vacuum Functional

Heating and vacuum functions can be added according to user needs.

-

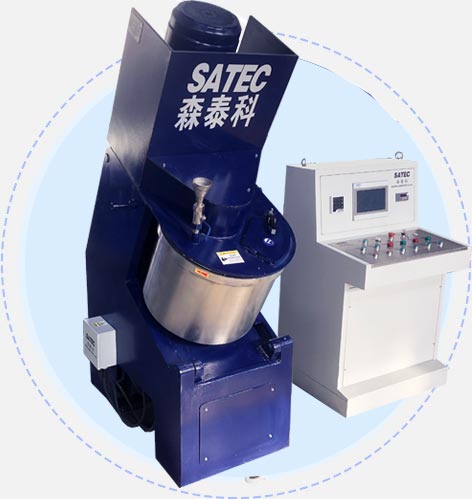

09Visual Control System

Equipped with an independent control cabinet, it can be connected to a PLC control system to achieve fully automatic control.

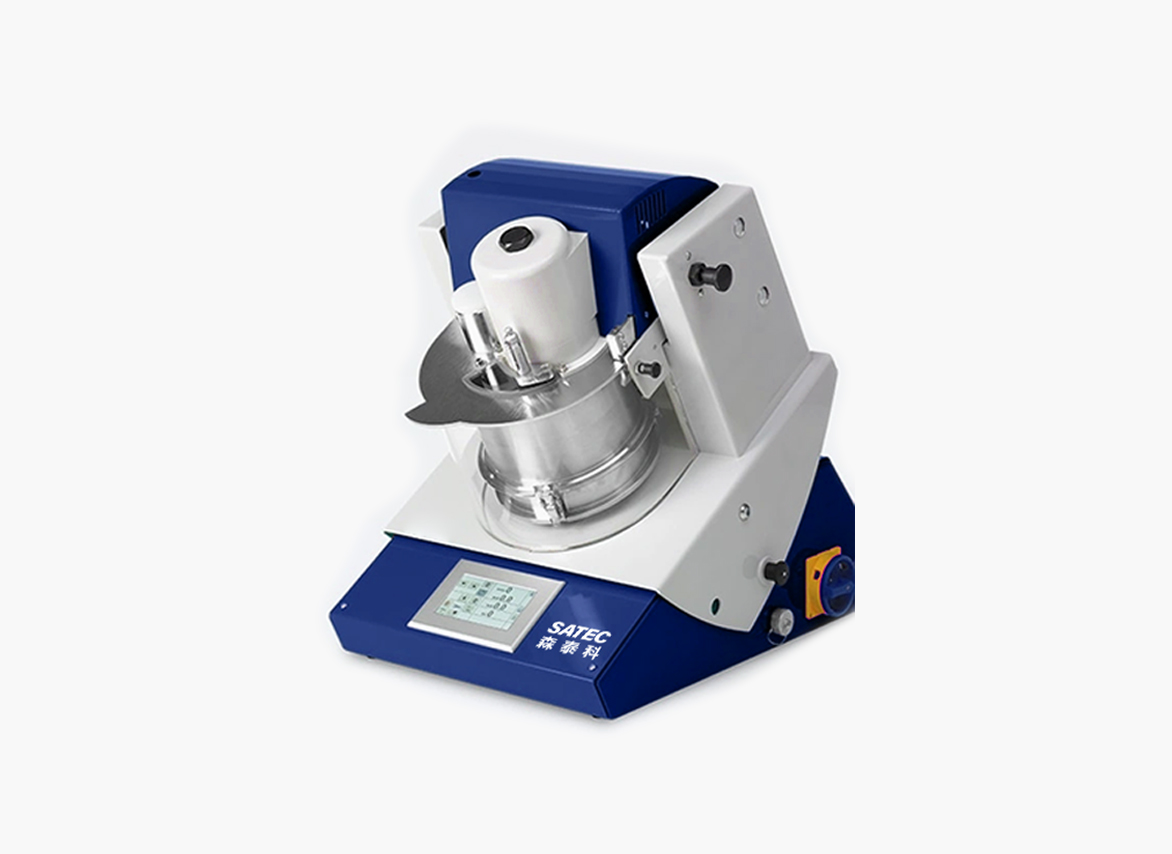

Laboratory Equipment – Professionalism and Quality Build a Brand

You may not have heard of SATEC, but your industry peers may be using our products!

-

Flexible

Flexible

Provides top-of-the-line laboratory mixing and granulation machines in China

-

Variety

Variety

Laboratory models are available to provide customers with thorough mixing tests for different materials.

-

Possesses unique professional technology and rich experience in manufacturing, debugging, mixing, and granulation.

SATEC's machines can achieve outputs of hundreds of tons per hour, and also meet the needs of research institutions, universities, and enterprises for mixing and granulation experiments of up to one liter at a time in the laboratory! For professional mixing and granulation, choose SATEC!

Industry Applications

品牌实力

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory

Convenient

Convenient