Glass

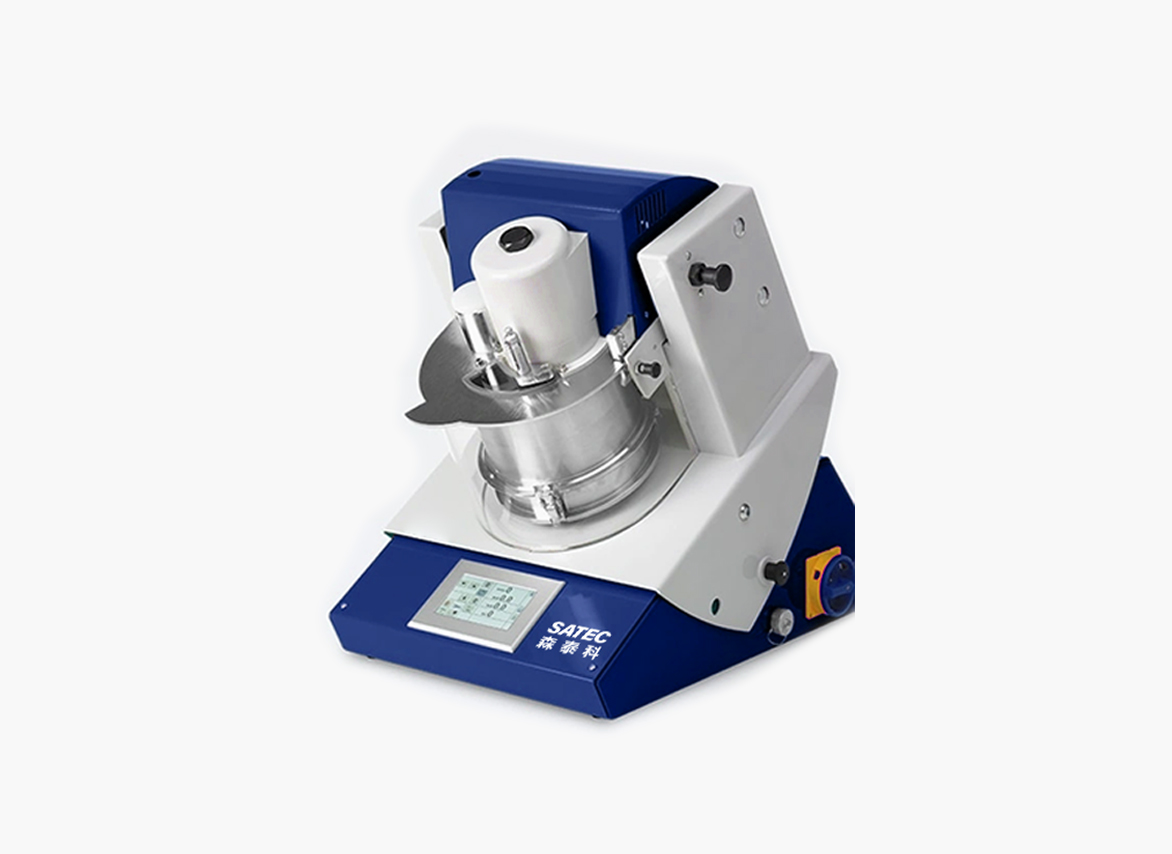

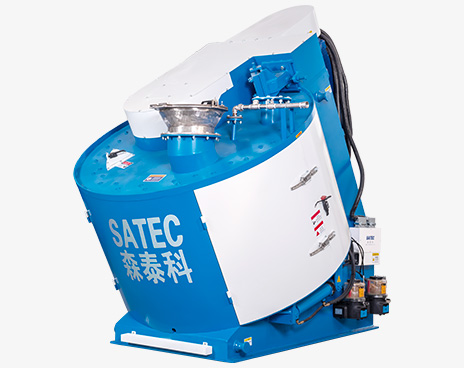

SATEC is a leader in glass mixers in China!

The final uniformity of the mixture in a glass mixing and granulation machine is a key factor determining glass quality.

SATEC has conducted a simple comparison of other types of mixers used in the glass industry. The advantages and disadvantages of each type are quite obvious:

Vertical: Slow discharge, requires pushing for discharge, fast discharge of viscous materials.

Horizontal: Fast center discharge, cannot fully discharge highly viscous materials.

Inclined: High uniformity, no dead corners, fast discharge, scraper allows for even faster discharge, fast discharge of viscous materials, low scraper wear, high speed and short mixing time.

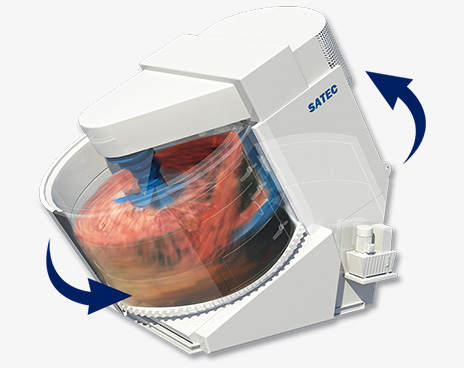

Advantages: The SATEC intensive mixer allows for individual component speed adjustments, improving mixing quality and material adaptability. Precise material residence time can be adjusted during mixing, and the mixer's speed is adjustable, making it suitable for relatively fast-moving materials. Multi-dimensional mixing helps improve material homogeneity and reduce residue.

Results: Highly efficient material mixing with minimal stratification is a key requirement for mixing equipment in the glass industry.

The SATEC intensive mixer is a uniquely designed, high-efficiency mixing device specifically for the glass industry in the domestic market.

Glass powder boasts excellent transparency, small particle size, and good dispersibility. This product undergoes multiple surface treatments to crystallize into fine powder particles, exhibiting good oleophilicity and affinity with other components in coating systems. It also possesses strong steric hindrance, allowing for relatively uniform distribution in paint films and improving their hardness, abrasion resistance, and scratch resistance.

Glass powder is an inorganic, cubic, hard, ultrafine powder particle, appearing as a white powder. Using high-temperature, high-purity silicon dioxide and alumina as raw materials, and undergoing an ultra-clean production process, it forms a disordered, transparent glass powder with stable chemical properties. It is an acid and alkali resistant, chemically inert, and low-expansion coefficient ultra-weather-resistant powder material. It is a scratch-resistant, highly transparent powder with small particle size, good dispersibility, high transparency, and good anti-settling effect. Through surface modification, it possesses good affinity and strong steric hindrance, allowing for easy dispersion in coatings. After film formation, it increases the fullness of the coating. Crystal-clear primers produced from this powder maintain clear transparency while providing excellent scratch resistance.

◎ Float glass ◎ Glass containers ◎ Glass fiber ◎ Glass wool ◎ Specialty glass ◎ Glass powder ◎ Waste glass slag

The following figure shows the volumetric loading capacity for a batch! Average mixing time is within 1 minute, and granulation is completed within 3 minutes!

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory